Building a floating solar plant is much more than assembling floats and panels on water. It requires careful planning, logistics, local adaptation, and teamwork. At Ciel & Terre, our construction teams play a key role in turning innovative ideas into operational floating solar projects across the world.

In this blog article, we take you behind the scenes of the construction process through the eyes of our 4 construction managers from EMEA, Taiwan, Japan and India. They give us a glimpse into their daily work, from anchoring operations to the realities of life on-site.

Today we are giving the floor to:

Each of them offers a unique perspective on what it takes to bring floating solar projects to life, from the first float to the final connection.

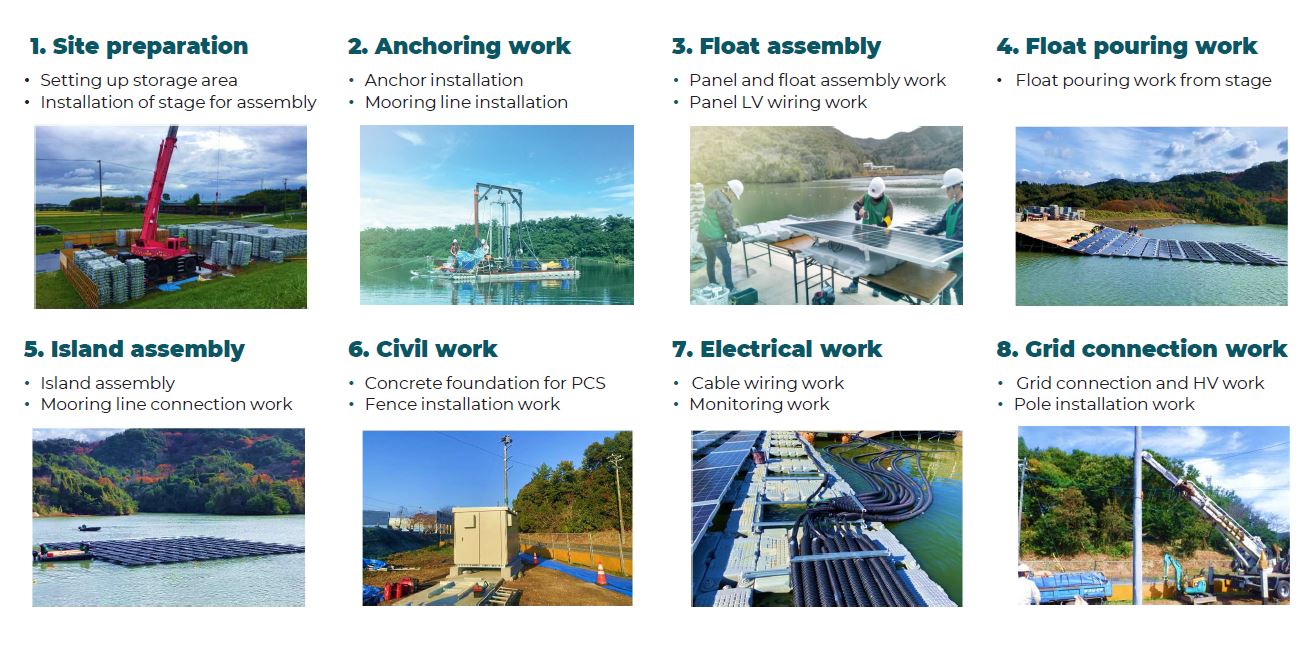

THE PROCESS OF Building a floating solar power plant

From site preparation to commissioning

Constructing a floating solar plant is a complex process, but our construction managers around the world agreed on the key stages that make a FPV project successful.

Site preparation and assessment

“The construction of a floating solar project in Taiwan typically begins with site assessment and preparation, including bathymetry surveys, soil condition analysis, and defining anchoring points,” explains Michael (Taiwan).

This careful preparation stage illustrates best practices applied across all subsidiaries, ensuring the project starts on a solid foundation and installations proceed smoothly.

Everything begins with thorough site preparation.

For Nobuhiro (Japan), this stage is crucial: “The most important point to build a floating solar power plant is the site preparation. When everything is well-prepared, we can respond quickly to any changes in the process and it is easier to assess the situation during work.”

In India, Mathavan highlights the many steps behind that preparation: site survey, setting up the site office, identifying the transport route and the storage areas and preparing and sharing documents. Each of these actions ensures that the project runs smoothly once installations begin.

For EMEA, Antonin explains that the work starts with the first anchors going in, but also with strong on-site organization. His teams set up storage and quality check areas, install the office, and handle all administrative procedures, creating a solid foundation for efficient, safe operations.

Anchoring and mooring systems installations

Once the site is ready, anchoring can begin. This stage ensures the floating system will remain stable in all conditions. Across all regions, our anchoring installation process follows the same objective: ensuring that every floating solar plant is safely, reliably, and durably secured. That is why, our construction teams follow the same main steps when installing the anchoring system :

1 – Selection and preparation of the mooring system

Depending on bathymetry, soil type, water level variations, and layout constraints, our teams determine the correct anchor types and mooring line configuration. This ensures the system is adapted to both the environment and project lifetime requirements.

“In India, we put a strong focus on choosing the right anchors and lines from the start. Testing and validating upfront ensures the whole plant stays stable in the long run.” — Mathavan from Ciel & Terre India Team

2 – Anchor installation and verification

We begin by installing the anchors according to site-specific conditions. Once in place, anchors are tested, most often through pull tests, to validate that it can hold the future floating islands.

“In Taiwan, we always start with anchor installation followed by a pull test. It’s our way to confirm everything is firmly secured before moving forward.” — Michael

3 – Progressive connection during floating island installation

As the units are launched on the water, the mooring lines are progressively connected. This approach maintains alignment, enables safe construction, and ensures the plant remains stable throughout deployment.

“In EMEA, we connect the mooring lines step by step as islands are positioned. It keeps everything safe, stable, and perfectly aligned.” — Antonin, Head of Construction C&T EMEA

Platform preparation and PV modules installations

Here again, our construction processes are fairly standardized across our offices. Platform preparation starts with installing mounting platforms, conveyors, and working tables. This organizes the assembly area and allows the team to work efficiently and safely.

Then, our construction team can start with the assembly of floating solar units. The panel installation process includes moving materials to the assembly area, fixing PV panels on floats, connecting the panels in series, completing earthing, dressing the cables, and installing string boxes.

Each action is carefully coordinated to maintain quality and safety near and on the water.

Towing, interconnection and testing

Once a unit is completed on the bank, we tow it into its position and connect the units to form the full array. DC and string cables are laid, grid earthing is completed, and electrical and voltage tests are performed to ensure proper operation of the floating solar power plant.

In EMEA, quality and safety are monitored continuously while connecting the FPV islands to the mooring lines. This ensures the array is secure and functions as planned.

Commissioning and site restoration

Finally, the work is inspected with the client during the commissioning phase. The site is cleaned and restored to leave no waste or damage behind after our teams have completed their construction work. This final step completes the project and hands over a fully operational floating solar plant.

The role of a construction manager:

Typical day as a construction manager

Usually, a construction manager starts his day with a morning briefing with the site team to review daily tasks and plan the work ahead. In Taiwan and Japan, this includes coordinating with subcontractors, ensuring that all work follows design specifications and safety standards, and performing on-site inspections and quality checks throughout the day.

In India, the day also includes :

- safety checks for workers and their PPE,

- a safety toolbox talk,

- reviewing project progress with sub-vendors,

- inspecting installation work,

- checking procurement and logistics,

- updating reports,

- and client updates.

In EMEA, the day often begins with a check-in on the mounting platform to anticipate the main steps, but, as Antonin explains, “every day is different because unexpected issues always arise.” At the end of the day, managers summarize progress, review the next day’s tasks, check materials, and organize photos to document the work.

Organizing and coordinating work across the teams

In any project management situation, coordination is key. But this is especially true when it comes to construction projects of this scale. That’s why our construction teams work closely with our clients, but also with the EPC team, and temporary contractors to ensure everyone is aligned and work progresses smoothly.

Smooth project delivery relies on clear planning, daily communication, and strong alignment between all teams on site. Work sequences are defined in advance (roles, timelines, and responsibilities), while regular progress checks and coordination meetings keep everyone aligned.

To avoid overlap, activities such as anchoring and mounting are phased carefully. When timelines are tight and tasks must run in parallel, teams rely on precise scheduling and contingency plans to prevent bottlenecks and ensure safe, uninterrupted operations. A site manager and works supervisor oversee the entire workflow, making sure teams stay synchronized from start to finish.

Quality and control checks during assembly and installation:

Quality control begins with checking the condition of the floats and accessories. In India and EMEA, torque checks are performed on all bolts, nuts, screw sets, and float caps. Our team also inspect the spacing between panels, the correct positioning of spreader bars etc, to ensure that the equipment complies with our standards.

Anchoring systems are also verified:

- In EMEA, each anchor is tested by applying twice the design load.

- While in India, the mooring lines are checked compared to the approved data sheets and inspected during installation.

- Finally, in Japan, inspections confirm that assembly follows the manual, that components are tightened properly, and that panels are not twisted once installed. When an island is complete, a third-party inspect the power plant to validate the overall quality of the work.

Managing and planning deliveries and storage:

Material delivery and storage are carefully planned to ensure safe and efficient access on site. Storage areas are organized before mobilization to ensure materials can be delivered, protected, and accessed safely. This includes :

- defining truck routes,

- securing sufficient land and closed storage areas,

- installing outdoor lighting,

- assigning security,

- and placing containers for parts storage.

Deliveries follow the supply chain schedule, and materials are stored close to the installation area.

“For delivery planning starts by estimating how many floats can be assembled per day and calculating the required quantities accordingly. For temporary storage, floats are sorted by type and placed in designated areas, with weights added whenever strong winds are expected, as is often the case in Japan.” – Hiroyuki and Nobihiro

Our Teams’ Most Significant Challenges

Across regions, each team has faced unique challenges during floating solar projects.

- In Japan, one of the most complex situations occurred when construction overlapped with other companies on site. This reduced the available space and disrupted the initial schedule. However, thanks to careful preparation in advance by the Ciel & Terre Japan construction teams, we were able to start operations earlier and even shorten the overall deadline.

- In India, one of our projects was particularly challenging, with steep 45-degree slopes, underwater cable installation, and constant shifts of the launching platform due to fluctuations in water levels.

- In Taiwan, the Changbin project was one of the most challenging, as it was located on a bay. In particular, it was necessary to manage the delivery of heavier-than-usual materials (pillar anchors), cope with frequent tides that limited working time to two days per week, and deal with strong winds in winter on the west coast.

- In EMEA, every site brings its own challenges, from soil type and lake geometry to water level variations, platform positioning, environmental constraints, and tight planning requirements, all of which require constant adaptation from the teams.

From planning to a fully operational plant.

Building a floating solar plant is more than assembling panels and floats. It requires planning, coordination, and adaptation. Our construction managers face challenges ranging from limited space and tidal variations to complex anchoring and tight timelines.

Success depends on thorough preparation, careful monitoring, and teamwork. Every anchor installed, panel mounted, and site adapted reflects the dedication, creativity, and expertise of our teams, turning ambitious designs into operational, sustainable energy solutions.

By Lilouann, Marketing