私たちの製品は

革新的で高品質。

あなたのニーズに応えるために。

の水上太陽光発電所建設に関わる実績

以上の技術者

以上の部品(コンポーネント)の検査

私たちは、多種多様な池や調整池などに適応可能な水上太陽光発電所用のフロート架台製品と、そのシステムを提供いたします。

私たちの水上太陽光発電所用のフロート架台製品と、そのシステムは、開発段階から蓄積されてきた研究開発結果に基づいて設計されております。研究開発は、信頼できる第三者機関によってテストされ、現在、世界中のお客様の 290以上の水上太陽光発電所プロジェクトで使われており、これらの実績は私たちの豊富な知見と私たちの製品とそのシステムの優位性を物語っております。

私たちのチームは、お客様のニーズと立地条件を十分に考慮した上で、お客様のプロジェクトに一番最適な水上太陽光発電所建設のためのフロート架台製品とそのシステムを提供いたします。

私たちのソリューション

私たちの製品は、UV耐性テスト、耐荷重テストなどを通じて25年間以上、問題がないことを第三者機関で確認済です。飲料水コンプライアンス:BS6920:2000企画に適合しております。

UV耐性30年間の耐性有

※ただし立地の条件により異なります。

耐荷重テストや疲労テストなど

各種テストを実施済

飲料水コンプライアンスを厳守

※BS 6920:2000企画に適合

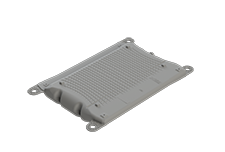

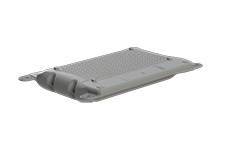

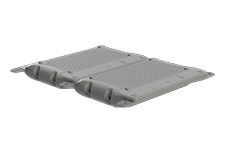

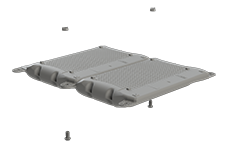

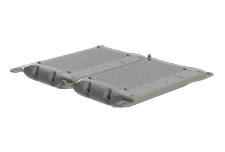

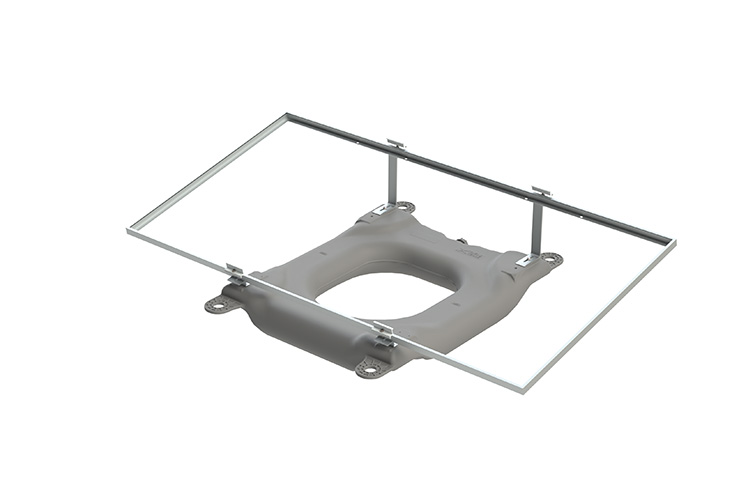

ハイドレリオ®エアー架台システム

メインフロート、

パネル架台、と PV固定システム、

第二フロート(大)、と (小)

固定金具、

メンテナンス用フロート、

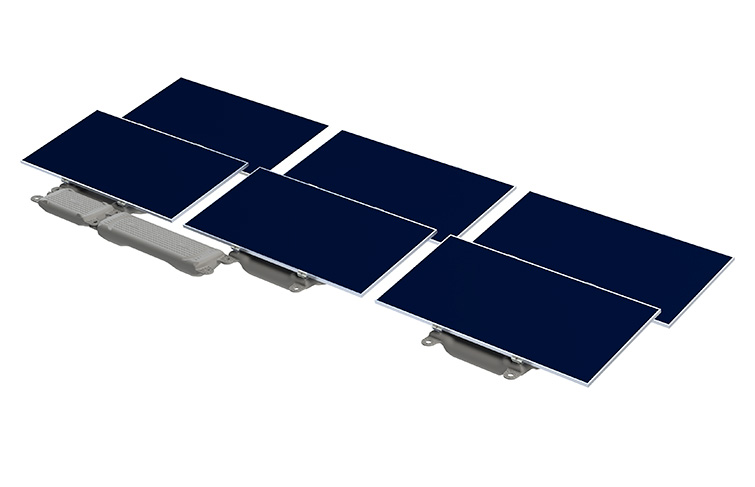

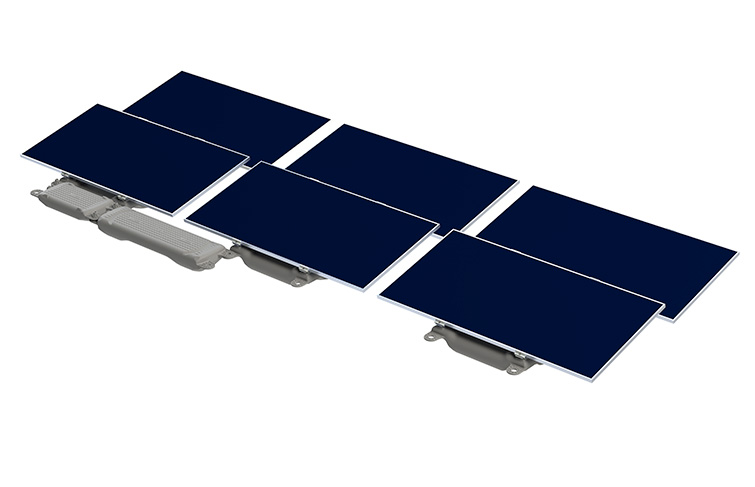

大型太陽光モジュール(M10とM12型)が対応可能

• 多種多様な条件のため池などに適しています。

• PVモジュールの各種サイズに合わせたフロート架台システムを提供できます。

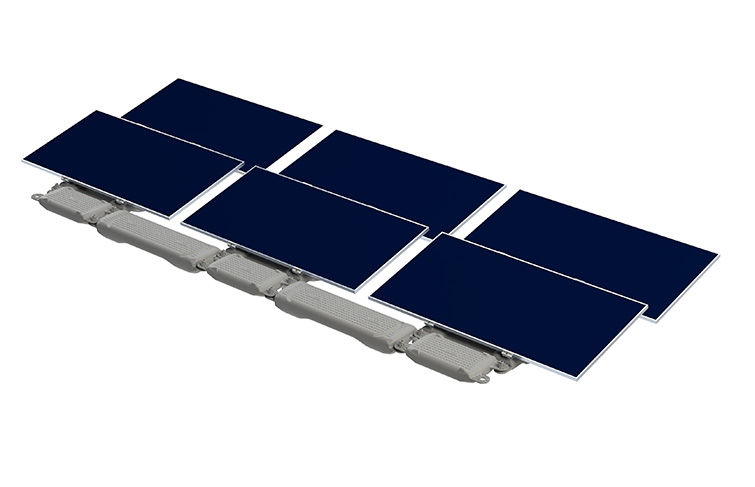

• メンテナンス用通路が存在することで、保守管理業務が容易となります。

•発電量を最大化するようにフロート・アイランドを設置いたします。

HDPE(高密度ポリエチレン)

• リサイクル可能

• 十分な浮力を保持

接続ピン

• 繊維グラスで強度を強化

メンテナンス通路用フロート

• 通路用フロートにより、保守管理業務が容易となります。