ご質問はありますか?

私たちがお答えします。

よくある質問

閲覧数の多いトピック

一般的な質問

質問事項

製品情報

立地条件

環境に関する

影響

フローティング

PV設計

電気仕様

アンカーリング

設計

建設

General Questions

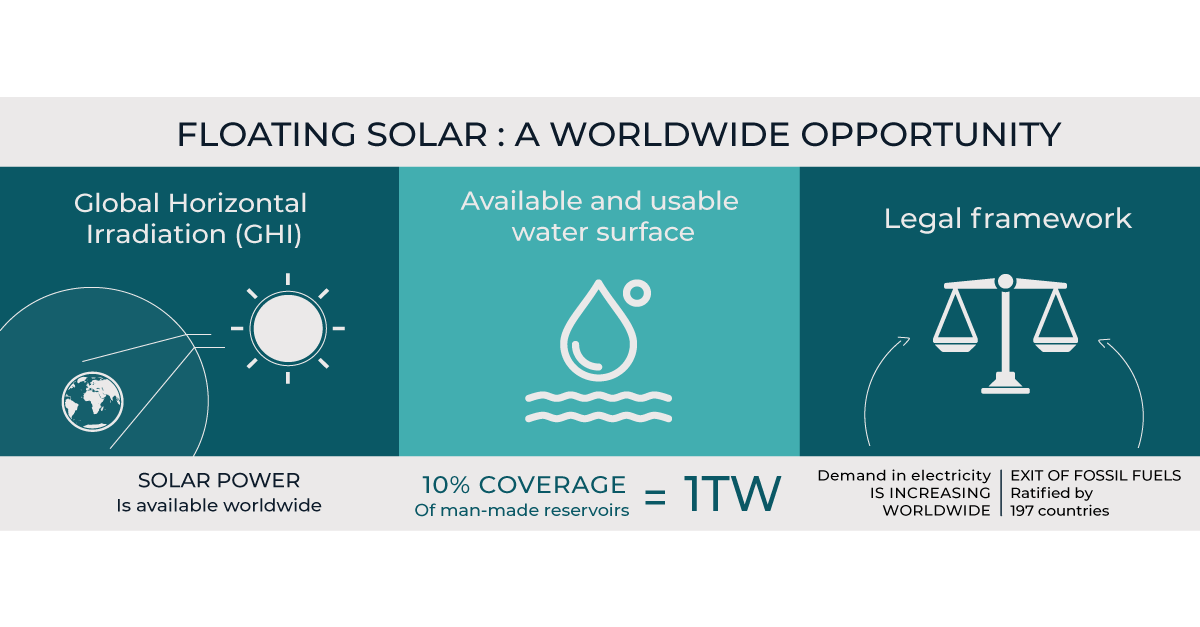

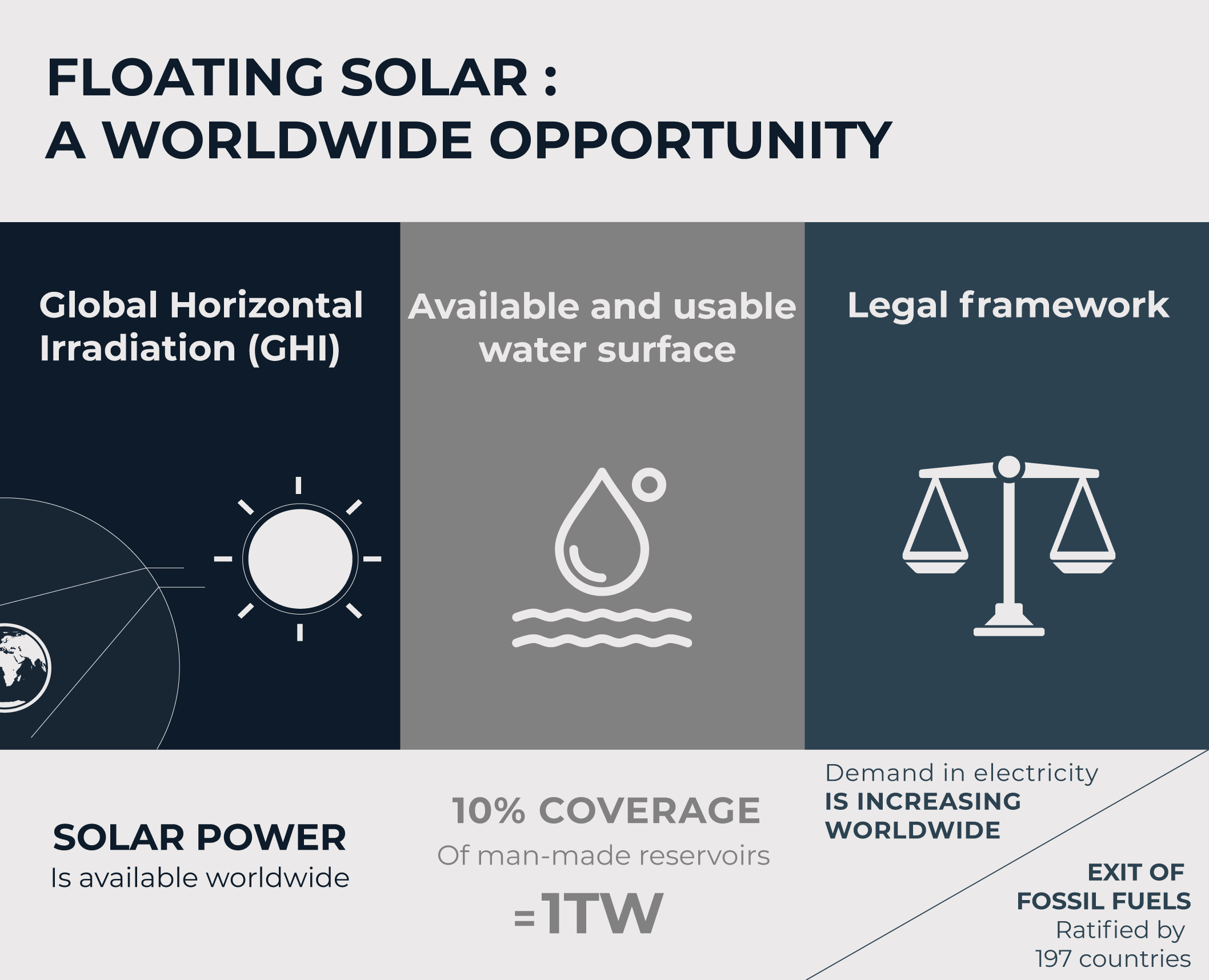

What is the yield compared to ground PV plants?

Thanks to water proximity, a cooling effect enhancing the energy production can be expected.

The Solar Energy Research Institute of Singapore (SERIS) observed a PV panel temperature 3 to 10 degrees lower on floating PV plants compared to rooftop systems in Singapore with a yield increase of 5 to 10%.

The Solar Energy Application Centre (SEAC) recorded a decrease up to 6 degrees in PV panels temperature in the Netherlands with a yield increase estimated at 2 to 3%.

.

What is the installable capacity per hectare?

A 1 MWp floating PV plant has a footprint of approximately 1 ha on the water body.

Distance between the floating arrays and the banks is required which means that the maximum coverage ratio of the water body is 65% on average.

What is the whole process for the floating solar product purchase?

After filling in the contact form, you will be put in contact with the closest Sales Department which will help you establish the technical and financial feasibility of your project.

The Sales Department will make the link with our Engineering team to execute the detailed anchoring design.

At the project implementation phase, we take care of the on-site delivery of our floating solar system. Then, we organize an on-site training session with our construction engineer to explain the assembly process to your teams.

Where can I buy Ciel & Terre's floating systems?

You can contact the closest office to your project location by checking the our international presence or by filling in the Contact form .

Our local teams will then contact you back to study your project.

Where are your products manufactured?

We manufacture our products in France, the USA, Brazil, Japan, South Korea, Thailand, India, Malaysia, Taiwan etc. For large scale projects, we may consider local manufacturing.

For more details, please, refer to the Supply and Procurement service page.

What are the selling points of our floating PV products?

At Ciel & Terre, with our FPV product we offer different advantages such as:

- We are pioneers in the floating PV market since 2011 and have the widest track record worldwide in terms of number of projects realized. This experience allows us to offer the most suitable technical advice and solutions.

- Our technologies have been tested by third parties to ensure the quality of the FPV system.

- Our solutions are adapted to the market. Since its first floating PV pilot in 2010, we have developed our products and our technical services to answer your specific needs. Now, we offer many options regarding floating products, plant configurations and anchoring solutions.

- We have 10 offices, 3 licensees and 40 manufacturing sites all over the world to provide a support as close as possible from our clients’ project.

- Throughout the project development and implementation, we will help and assist you technically with a wide range of service.

- We offer cost competitive solutions that have been developed to be price-competitive in their market while ensuring quality of materials and products.

What is the delivery time?

Delivery time will vary depending on your project location and the availability of the production lines.

The floats are produced in just-in-time flow and a minimum of 8 weeks after the order placement is to be expected before the first delivery on the site.

Do banks financially support floating PV projects?

Yes, many of the floating PV plants built in the world have been financed and supported by banks including some of the world’s top-ranked banks. For example, in Japan, projects have been financed by both national and regional banks, and in France, the 17 MWp O’MEGA1 project has been financed with around €12 million of non-recourse financing.

What is the product standard warranty of our systems?

We offer a 10-year warranty for our FPV systems, to cover replacement and repair of any potential defective component of the product. An extension of additional 5-, 10- or 15-year warranty can be discussed.

How is O&M done on the floating PV arrays?

Maintenance walkways between PV panel rows allow operators to move easily on the floating PV plant to do O&M tasks such as PV panels cleaning and parts replacement.

In addition to operation, preventive and corrective maintenance tasks must be considered.

The O&M manual, including checklists and controls, is delivered to clients prior to plant operation.

Discover our maintenance services, or contact us to learn more about our offers.

Product

What are the components of Ciel & Terre's floating structures?

Floats are made of HDPE (High Density Polyethylene), connection pins are Polypropylene and PV panel fixation is Aluminum. Additives are added to the raw materials to ensure the product lifetime.

Can the color of the floats be changed?

Float color cannot be changed.

The grey color of the floats allows UV resistance and light reflection.

What is the buoyancy of Ciel & Terre's floating structures?

Our floats have been designed to enable operators to move easily on the floating PV array and safely carry out O&M.

What are the possible tilts for Ciel & Terre's floating solar systems?

Our floating solar systems offer several tilts to the floats to answer different market needs. To see the available options, find more information on our Products page.

DOES CIEL & TERRE HAVE A SOLUTION TO PREVENT BIRD EXCREMENTS FROM DECREASING THE PANEL’S YIELD?

Some solutions like lasers or distress sounds have been identified and should be studied case by case. However, as this is a specific matter to each site, we do not recommend a specific solution.

What tests have been conducted to determine Ciel & Terre's floating structure resistance?

We test our floating structures and their fixation with mechanical tests (fatigue and static) and wind tunnel tests by 3rd party institutes.

Are Ciel & Terre's floating solar systems certified?

As floating solar is a recent concept, there is no certification regarding the floats yet. We base our test protocols on relevant standards and have, for example, obtained certifications for drinking water compliance. In addition, our design methods are certified as well.

What is the lifetime of Ciel & Terre's floating solar structures?

We designed our floating solar structures to withstand a period of over 25 years.

The floats can be recycled at the end of their lifetime since the HDPE and aluminum are recyclable.

Site conditions

How to identify water bodies where floating solar can be installed?

Ideal water body characteristics are:

- Regular shape

- Limited depth and water level variation

- Road access

- Space on the banks for construction and storage

- Proximity with the grid is a plus for the project development

But, almost any water body could be a candidate for floating solar. We are happy to assess your site at no cost to you. Contact us

Can Ciel & Terre's floating solar structures be installed on drinking water ponds?

They are compliant with the standard BS 6920:2000 (odor & flavor test for non-metallic material for use with drinking water), which proves that it is suitable for contact with water intended for human consumption.

Can Ciel & Terre's floating solar structures be installed on salty waters?

The PV panels and electrical equipment will also need to resist these conditions.

An appropriate O&M plan, especially regarding the electrical parts, will have to be considered.

Can Ciel & Terre's floating solar structures be installed on polluted waters?

Can Ciel & Terre's floating solar structures resist to high winds?

The floating PV plant is designed case by case and its anchoring is defined with the Client, according to site conditions.

Can Ciel & Terre's floating solar structures be installed on oceans or seas?

Can Ciel & Terre's floating solar structures be installed in cold environments (frost and snow)?

What happens in case of drought?

If the water body bottom is not flat or has some obstacles (pipes, rocks…), the site is not eligible due to the risk of damage to the floating system. Contact our teams to evaluate the feasibility of your project. Contact us

Can Ciel & Terre's floating solar structures be installed if there is a risk of overflow?

However, Ciel & Terre must be informed of potential overflow in order to consider it when executing the anchoring design.

Are Ciel & Terre's floating solar structures compatible with fishing and fish farming?

Environmental impacts

Does floating solar prevent algae growth?

Covering a pond with floats means that less sunlight is available for algae to grow which reduces their proliferation.

An environmental consultant can help you assess the impact.

Do your floating PV technologies prevent evaporation?

Since a significant part of the water body will be covered or shadowed by the floating PV plant, you can expect a reduction of evaporation. However, it might be difficult to quantify as it is specific to climate conditions.

What is the impact of our FPV structures on aquatic life?

Both light and heat are expected to decrease creating a new balance for the reservoir’s fauna and flora. The specific impacts on a site can be investigated with the help of a local environmental impact specialist. Also, environmental consultants usually highlight that under 50% coverage, the floating PV plant impact is limited.

What is the impact of your solutions on water quality?

Our floats are made of HDPE (High Density Polyethylene) which has a neutral impact on water. Indeed, our systems are compliant with the standard BS 6920:2000 (odor & flavor test for non-metallic material for use with drinking water) which proves that it is suitable for contact with water intended for human consumption.

Are there any permanent effects on the site’s environment after the operation decommissioning the plant?

There are few permanent consequences on the site’s environment since our floating solar systems are made to be as neutral as possible. Moreover, during the decommissioning phase, the floating PV arrays will be dismantled easily on the banks.

Are your technologies recyclable?

HDPE is a recyclable material. For instance, there is a set of profitable channels for the use of recycled HDPE. Moreover, aluminum parts are also recyclable.

Floating design

Is there any limitation of size or capacity?

As an example, the 70 MWp project of Anhui Cecep (China) is composed of 13 floating PV arrays. See project

What is the buoyancy of Ciel & Terre's floating solar structures?

Can the floating PV arrays move and hit the banks?

What happens when the water level drops?

What PV panels orientations are possible with Ciel & Terre's floating structures?

Depending on the products chosen, different solar panel orientations can be advised by our teams:

- Conventional (north-south configuration)

- Dual orientation or duo pitch (east-west plant configuration)

Sun-tracking is not available.

Are all the PV panels compatible with Ciel & Terre's floating solar structures?

For our Hydrelio® system, PV panels are assembled with the main floats.

What is the bi-facial PV panels performance on Ciel & Terre's floating solar structures?

Can frameless PV panels be installed on Ciel & Terre's floating solar structures?

How to install the electrical cables between the floating PV arrays and the banks?

Based on our experience and collaborations with electrical engineers, we recommend 2 options:

- UV resistant-electrical conduits fastened on isolated floats between the floating arrays and the banks

- UV resistant floating conduit with electrical cables inside.

Is it safe to have PV panels connectors in contact with water?

What is the information required for the plant design?

For a first site assessment, the information we require are

- The GPS coordinates of your site

- The site conditions including: pond type, water type, max depth and water level variation

- The electrical equipment main features.

These data will allow our engineering teams to determine the exploitable surface of the pond and the maximum capacity for your floating PV plant. Contact us

Electrical specifications

How does water proximity impact electricity generation?

Water proximity is an advantage for your floating plant.

Water provides a natural cooling effect when the production is at its maximum. This phenomenon reduces the temperature variation peaks thus provides a cooler environment. This cooling effect enables PV panels to generate more power.

HOW IS THE PV PANEL CABLING DONE?

Cables are connected behind the PV panels and fixed to the frame to avoid any contact with the water.

Is it safe to have PV panels connectors in contact with water?

We recommend reducing risks of contact with water by attaching DC cables to the PV panels before the floats are launched on water, by using stainless steel clips for instance.

We also recommend to used watertight and UV-resistant cable conduits.

Does the material need to have a BOS specification (weight, IP code, size)?

Because of permanent movement, cables suppliers recommend using copper cables.

Possible local regulations regarding electrical equipment must be observed by the EPC.

Are the inverters installed on the floating PV arrays?

In most cases, plants are designed with central inverters located on the banks and junction boxes on the floating PV arrays.

Depending on the product chosen, string inverters can be installed on the floating PV arrays. Our project engineering team can advise the EPC regarding this matter.

How does grid connection work for floating PV plants?

What are the recommendations for earthing/grounding?

We recommend complying with local electric standard.

On the Hydrelio® products, PV panels grounding holes are used to do the grounding between PV panels.

How can I protect the DC cables?

How to install the electrical cables between the floating PV arrays and the banks?

Based on our experience and collaborations with electrical engineers, we recommend 2 options:

- UV resistant-electrical conduits fastened on isolated floats between the floating arrays and the banks

- UV resistant floating conduit with electrical cables inside.

Anchoring design

What is the information required for the anchoring design?

The anchoring design is executed at an advanced stage of the project planning, when the final floating array design is approved. The critical data to perform an anchoring design are:

- Topography of the banks

- Bathymetry

- Water level variation (over the lifetime of the plant)

- Waterflow data if there is any wind speed on site is calculated from national building code and approved by the client.

What are the possible anchoring systems?

Our engineering team will advise the most relevant anchoring system among the following, depending on your site conditions and your preferences:

- Anchoring at the bottom of the reservoir

- Anchoring at the banks

- Hybrid anchoring mixing banks and bottom anchoring

What type of anchors can be used?

At Ciel & Terre, we propose three main types of anchors: drilled anchors, percussive anchors and concrete blocks.

Nevertheless, if none of these anchors can be used, our engineering team will study other types of anchors.

How does water level variation impact the anchoring system?

Therefore, it is highly critical to perform the anchoring design with accurate and reliable data, so the anchoring system is safe at any water level.

Can the floating PV arrays move and hit the banks?

Because it is anchored with several anchors on each side, the movement of the floating PV array will be limited. During the anchoring design execution, our engineering team calculates the movement of the floating PV plant and ensures that it won’t hit the banks.

Can the floating PV plant lie on the bottom of the reservoir?

In case of droughts, floats will lie on the bottom of the water body without being damaged.

If the water body bottom is not flat or has some obstacles (pipes, rocks…), the site may not be eligible due to the risk of damage to the floating system.

What is the resistance of the anchoring system?

Our anchoring systems are designed to resist environmental loads: wind, waves, current.

First, we calculate the wind loads thank to several technics : with CFD, with wind tunnel tests and with wind speed calculated from national building code.

Second, we measure wave loads based on the floating solar island, reservoir layouts and wind speed.

Finally, we analyze waterflow loads based on the FPV array and reservoir layouts and waterflow data.

Do the mooring lines rust?

Equipment must be chosen depending on site conditions. Usually, galvanized steel cables and polyester ropes are used to mitigate the risk of corrosion.

Does Ciel & Terre supply the anchoring and mooring systems?

At Ciel ∓ Terre, we include the anchoring design with the design of the FPV plant because both are indivisible.

Firstly, we define the location of each anchor and the applicable load on each anchor and each mooring line length. In addtion, we provide the anchoring material specifications too.

Secondly, and as the floating solar expert with a strong experience in anchoring, we provide you the support you need to ensure your floating PV plant is correctly anchored.

Finally, our construction team manage the supply and the installation of the anchoring system.

Click on the following link to discover our services: Discover our services, or contact us to learn more about our offers: Contact us.

HOW IS FLOATING PV ARRAY MOVEMENT AVOIDED DURING CONSTRUCTION?

First of all, the anchoring system must be installed prior to float assembly and connected to FPV blocs during the installation. Then, additional temporary anchors and mooring lines are installed to maintain the arrays. For this reason, the temporary anchoring system must be as resistant as the final anchoring.

Construction

How to mount our floating solar systems in case the banks are too steep?

If the banks are too steep, we can install a wooden platform with scaffolding to reduce the banks’ slope for safety reasons.

What area is needed for construction?

There is no requirement in terms of installation platform’s size. However, the bigger the area is, the better. To reach a minimum efficiency, we recommend a 10m large area with a length equal to one string of PV panels.

How to assemble the Hydrelio® floating PV array?

The assembly process depends on the system we install.

For instance, with our Hydrelio® range, the assembly is simple, like a Lego-type construction.

At Ciel & Terre, we provides:

- Manuals and supporting documents

- A training session on site at the start of the assembly

- Advice to increase the assembly efficiency

- Construction drawings in order to ease construction for the installation team

We can also manage the construction of the floating solar island and its anchoring. You can contact us to have more details and visit our services page to learn more about our construction services : Discover our services.

How many people are needed to install a floating solar plant?

We recommend a team of 15 persons. To improve the mounting rate for large-scale projects, multiple teams can work on separate areas.

Which tools are needed to install a FPV structure?

It depends on the range.

Considering our Hydrelio® system, no heavy or specific tools are required. During the planning phase, our project manager will provide a list of tools.

In addition, a boat and all the adapted protective equipment (PPE) such as life jackets, helmets, security boots, etc. are mandatory.

How are the floating PV arrays launched on the water?

When two or three rows of floats and PV panels are assembled, the construction team pushes the island on the water manually to liberate space on the assembly platform.

Once a block is completed (the size of each block will be defined with Ciel & Terre during the planning phase), they can be towed by boat to their final locations and connected to the anchoring system.

How long does it take to install a floating PV plant?

To install the floating array, including connection to the anchoring system and electrical cables installation, an average ration of 2.5 PV panels per hour and per worker can be considered. For instance, a team of 15 persons would install about 12 kWp/hour.

How do you avoid the Hydrelio® floating PV arrays moving during the work?

If the banks are too steep, a wooden platform with scaffolding should be installed to reduce the banks’ slope for safety reasons.

How to secure floating PV plants?

The plant can be secured by:

- Video surveillance / CCTV next to the electrical installation on the banks

- Fencing the land

- Installing a floating barrier around the floating PV plant

Is there a training session for the installation?

At Ciel & Terre, we provide a training session on site at the start of the assembly and give advice to increase the assembly efficiency. In general, the typical duration is 2 days and can be adapted depending on your needs. Our construction team can also support you with the installation of the floating solar plant and its anchoring.

To learn more about our Services: Discover our services.

私たちの記事、もっと詳しくは…

The ponds compatible with floating solar: what are the conditions?

Ciel & Terre adapts anchoring to floating solar projects constraints

Floating solar-friendly ponds: what are they?

他に質問はありますか?

私たちはきっと、その答えを持っているはずです ご遠慮なく、私たちのチームにご連絡ください。