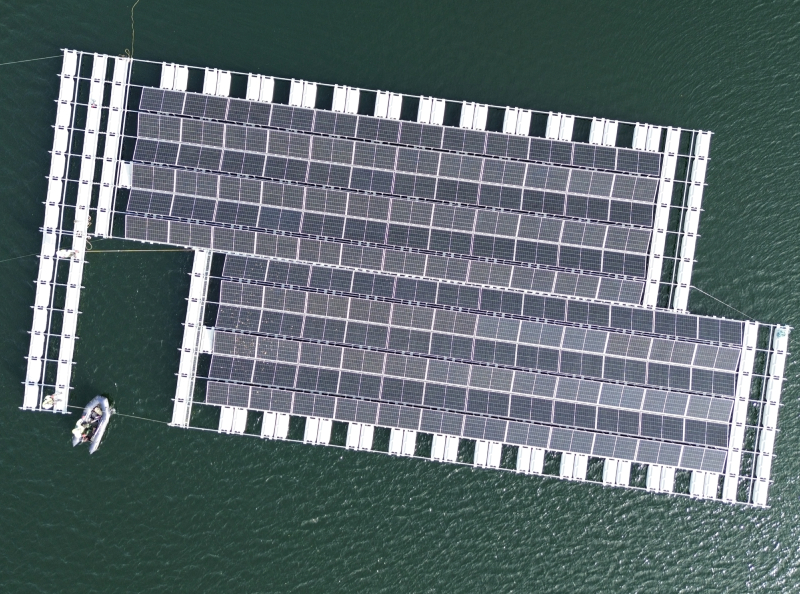

WattRack® floating solar system:

high-density & easy maintenance

Scale up your floating solar plant : make it denser, bigger & more efficient.

WattRack® is made to meet the evolving demands of floating solar projects by combining structural stability, increased power density and long-term profitability of your floating solar projects.

Engineered to maximize density, optimize anchoring design, and simplify maintenance, WattRack® enables you to deploy more PV modules per hectare while lowering overall costs.

Benefits of WattRack®

floating solar technology

Denser floating solar islands to maximize profitability with WattRack®

WattRack floating solar solution increases the power density (Megawatt per hectare) of the FPV project by removing the traditional maintenance alleys. With a compact layout and optimized racking structure, you can install significantly more PV panels per hectare.

Higher

energy

yield

Competitive

CAPEX/

OPEX

Densify your

power plant :

Up to

2.2MWp/ha

East-West floating solar configuration: maximize size, minimize costs

Thanks to its East-West floating solar layout, the loads applied to the floating structure, especially in windy conditions, are reduced. This allows us to build larger floating solar arrays with fewer anchoring points, simplifying installation and making it a cost-effective solution.

Tailor-made floating solar solution

WattRack® offers full adaptability to meet your project's technical requirements and environmental constraints.

- “All-in Electrical Solutions” : cable management (cabletrays, grounding...), on-water inverter support & dedicated electrical alley

- Tilt angles: Available in 5° & 12° (customized angles upon request)

- PV modules compatibility : Supports all standard market sizes

- Floating array size : No limitation based on project specifications

- Easy maintenance with a dedicated motorised trolley

Smooth maintenance and

full mobility on your power plant

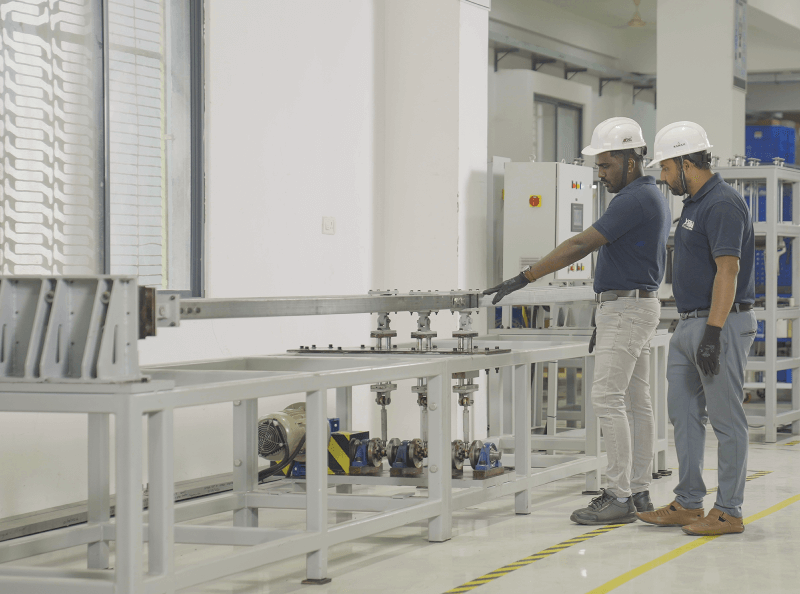

WattRack® trolley system : ride on the structure

To meet growing operational needs, WattRack® integrates a motorized trolley system that rolls directly over the floating solar island. You can reach every part of the power plant, even anchoring points, with ease.

This system transforms maintenance making operations quicker, easier and safer. The WattRack® trolley reduces operators' efforts, no more carrying heavy panels or inverters over long distances. This speeds up interventions thanks to onboard storage and integrated replacement tools.

Above all, the trolley ensures safe working conditions with a secured rolling system, helping teams save time, reduce fatigue, and operate with greater confidence.

Trolley key properties

- Electrical Motorized cart ensuring smooth circulation across the FPV plant: 5km/h speed & 5h autonomy

- Control panel integrated to the trolley to move in every directions

- Maximum security with a safe rolling system, parking brakes, Safe throttle, and anti-derailing system

- Light yet powerful : capable of carrying up to 300kg without affecting FPV buoyancy.

- High material robustness using components engineered to withstand diverse environments.

- Ergonomic design : storage spaces for solar panel stacking and integrated tool for efficient PV module replacement.

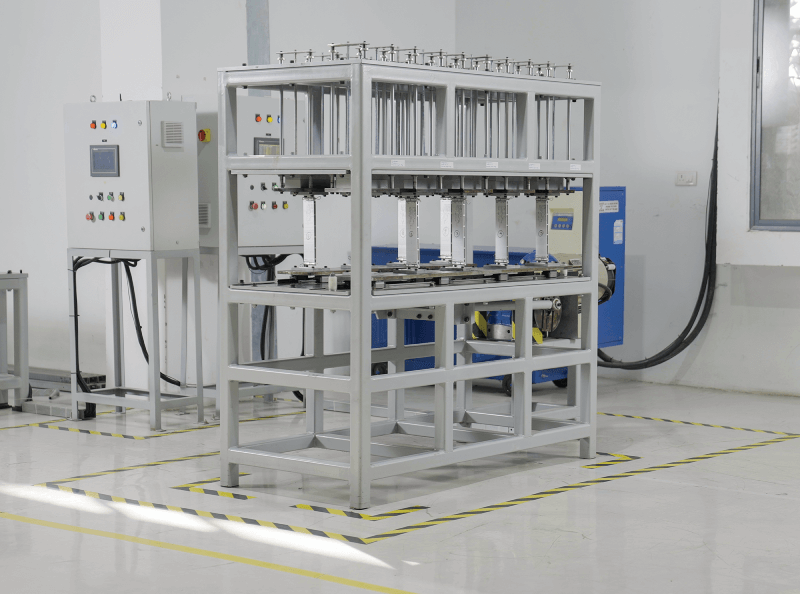

WattRack® quality and long-term reliability

Denser floating solar islands to maximize profitability with WattRack®

Reliability is at the core of our floating solar solutions. For WattRack®, we have conducted specific tests tailored to this new structure, validating every component under real-world conditions.

Test protocols include:

- Rail and fixations fatigue

- Wave fatigue

- Thermal behaviour

- Tensil resistance on all parts

- Anchoring tests & simulations

- Grounding

Designed to last up to 30+ years

WattRack® uses robust, high-quality materials to ensure performance and durability:

UV-resistant

materials, stabilised up to 30+ years

Durable & recyclable

• Floats made with high-quality HDPE

• Coated metallic parts

Corrosion

Zinc & magnesiresistanceum coated steel for enhanced durability

Wind

design to withstand extreme wind conditions

Snow

adapted to snow environment up to 1,2kN/m²