Floating solar systems are built to operate for 30 years or more, which implies that the power plant will and must deal with environmental impacts throughout its entire operating lifetime.

To ensure its reliability maintenance process has to be settled, monitored and executed over time. In this article, we will explain how maintenance and operation work in floating solar power plants, why they differ from ground-mounted solar, and what kind of expertise is required to keep installations performing year after year.

Maintenance and operation in floating solar: what makes it unique?

The challenging surrounding water environment

To understand floating solar maintenance, we first need to look at how a floating plant behaves over time. Unlike installations on land, floating PV is constantly interacting with water: waves, currents, wind loads, and even wildlife coming from above and underwater. In this water environment, the power plant is constantly in motion, more or less intensely depending on the site location.

Considering those additional parameters, this means that maintenance operations in floating solar aren’t just about checking that the modules produce electricity. It is about monitoring how the floating structure, anchoring system and electrical components evolve with time.

What matters most in floating solar maintenance ?

The first key component to pay attention of in floating solar is the anchoring and mooring system. This includes the anchors, the mooring lines (ropes, chains etc.) and mooring bars. Indeed, it is the first safety element for the FPV plant to remain in its place on the lake. If it fails, the entire plant is at risk.

Right after that come structural elements such as floats and their fastenings, which will withstand fatigue & mechanical stress caused by water motion that creates dynamic loads.

While many operators still use maintenance procedures designed for ground-mounted PV, floating plants require a different mindset: a mix of above-water and underwater monitoring, structural checks, electrical inspections and long-term behaviour tracking.

Of course, depending on the site’s location, climate and characteristics, the O&M procedure should be adapted and customised to the project’s needs. For instance, for typhoon regions, preventive inspection may be necessary to verify the proper condition of the anchoring system.

The specific FPV maintenance process and interventions

Ciel & Terre’s approach in maintaining floating solar power plants

Given this rather challenging environment, it makes sense to develop new maintenance methods to increase the speed and efficiency of interventions.

As experts in floating solar power, we began developing solutions in 2018 to better support our customers and their projects, particularly for our Japanese projects, which are exposed to periods of high winds several times a year. By then, we already had solid experience and feedback from power plants that had been in operation for several years.

Today, depending on the region, we have dedicated teams and processes for O&M. We have broken down the scope of work on a floating solar power plant into four areas :

- Floating solar structure : floats, connections, PV panels

- Anchoring : whether it is on banks and/or underwater, our team are trained for any scenario.

- Electrical devices : located on the structure and on the shore

- Surrounding : interventions on vegetation on the site, for example

What maintenance services are needed for floating solar plants?

Based on this area segmentation, there are a range of O&M solutions specifically tailored to floating solar installations.

Here is an overview of what maintenance operations of floating solar may include in practice.

Maintenance for the floating solar structure

- Visual checks* on floats, walkways, float-to-float connections, PV panel fixation system, cable trays, conduits, and other related components

- Drone inspections* of the entire power plant.

- Storage of some FPV components

- Repair and replacement of damaged parts

- Cleaning of photovoltaic modules

*The number of inspections is defined with the client, based on the site’s needs (climate, location etc.)

Anchoring and mooring maintenance interventions

- Above water inspections of the anchoring system on the bank and on the FPV island.

- Repair and replacement of damaged parts

- Underwater interventions: change of mooring lines parts, anchors etc., using our divers

Electrical Device Maintenance & Monitoring

- Inspection of system-related switches and molded case circuit breakers, surge protection devices, and terminal blocks

- Visual and electrical inspection of PV modules and inverters

- Functional check of monitoring systems

- Annual high-voltage equipment testing and submission of test reports

Site Interventions & Extreme Weather Response

- Weed and vegetation management

- Weather monitoring to anticipate inspections

- Pre and Post-typhoon / heavy rain / earthquake inspections

- Rapid response teams for emergency repairs

Field experience and knowledge sharing: Japan–Taiwan collaboration

Thanks to our maintenance teams located in several regions around the world (Taiwan, Japan, Europe), we have been able to increase our expertise in the field of maintenance and, above all, create genuine collaboration and experience sharing between our crews.

As recently as the summer of 2025, during the typhoon season, our O&M team from Japan supported Ciel & Terre Taiwan in repairing damages on several floating solar plants, including competitor systems. This collaboration allowed faster interventions thanks to shared maintenance methods, field experience and anchoring diagnosis techniques.

Following this joint operation, both teams decided to formalise regular experience-sharing sessions to improve maintenance strategies for harsh-weather conditions.

This example illustrates an important aspect of floating solar maintenance: the ability to adapt maintenance processes using real operational feedback from different regions and site conditions.

New floating solar technologies, new maintenance approaches

Traditionally, in floating solar, the maintenance is mainly done whether with walking inspections and/or drone inspections. Operators walk along the plant’s maintenance walkways, transporting equipment by hand or using specialized hand carts.

But what if you have no maintenance walkways anymore? Indeed, with our new floating solar technologies, Fusio® and WattRack®, there are no longer maintenance alleys, which has deeply transformed the way we operate the floating solar power plant.

Fusio® : Navigate with the O&M catamaran

Fusio® floating solar platform is made with triangular floats, combined one to another which makes a honeycomb structure. It implies that there is no walking path on the structure.

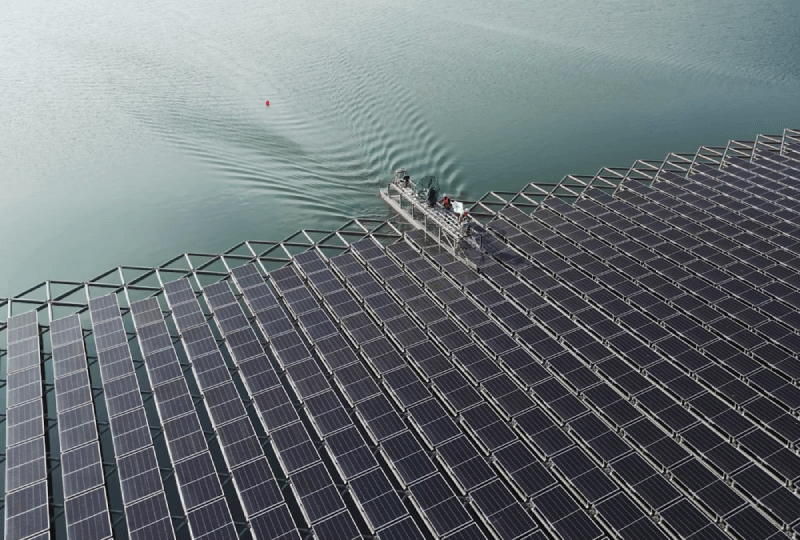

The catamaran has been developed by our R&D team to navigate over the PV panels and to operate all the parts of the power plant. It makes the maintenance team’s work more efficient while improving staff safety and reducing physical fatigue.

This unique boat is designed to support all types of maintenance operations :

- Easy transportation of all tools and devices needed for the repairs

- Move smoothly between rows of PV modules

- Perform visual checks and minor interventions without repeatedly returning to shore

- Clean the PV panel without effort thanks to the integrated PV modules cleaning system

WattRack® : Drive over the structure with the motorised trolley

Just like with Fusio®, WattRack® has a specific design without any maintenance alley between the PV modules, it is therefore no longer possible to walk between the rows of panels. The aim is to increase the capacity of the project and therefore install more solar panels.

However, as with any floating solar power plant, it is necessary to be able to access the plant, whether to clean the solar panels or to replace parts. That is why our R&D team has developed a motorized trolley that allows access to all areas of the plant by traveling directly on the structure’s rails.

Thanks to this cart-based maintenance solution, all maintenance operations can be performed, such as:

- Reach all parts of the PV island safely and effortlessly with the electronic control panel of the trolley

- Carry tools and replacement parts during maintenance operations with minimal physical effort

- Use integrated tools to assist the PV module replacement

Adopting a dedicated approach to floating solar maintenance

Approaching maintenance and operation of floating solar plants requires more than applying standard solar O&M routines. It means understanding how floating structures, anchoring systems and electrical components behave over time in a dynamic water environment.

Effective maintenance starts with site-specific design, continues through regular inspections, and relies on feedback from real operations and observations on site.

By combining field experience, adapted tools and long-term monitoring, floating solar plants can remain safe, reliable and productive throughout their expected lifetime.

By Chloé, marketing