Floating photovoltaic systems are an innovative energy alternative, particularly suited to areas where land availability is limited. However, their effectiveness depends on reliable anchoring, guaranteeing their stability against site characteristics and environmental conditions. For floating solar projects, the choice of anchoring technologies and methods depends on factors such as water depth, soil type and local weather conditions.

At Ciel & Terre, as recognised experts in floating solar, we have a thorough understanding of all these parameters and we design customised anchoring solutions to suit each site. This article explores the different anchoring technologies and methods we use to optimise the performance and durability of FPV installations.

Anchoring technologies for floating solar power plants

Screw, plate and dead-body anchors: adapting the solution to the soil type

The anchoring of floating solar power plants is based mainly on four main categories of solutions adapted to site conditions:

- screw anchoring,

- dead-body anchoring,

- plate anchoring

- and pillar anchoring.

To choose the right anchoring technology, we carefully assess the nature of the soil so that we can recommend the most suitable type of anchoring.

Screw anchors

Indeed, screw anchors are ideal for cohesive soils, such as clay, silt or rocky substrates. It can be installed using an auger mounted on an excavator, a tripod developed by Ciel et Terre or by divers. This solution is often chosen for bank and bottom anchors.

Plate anchors

The plate anchoring involves using anchors with a large load-bearing surface, often made of cast iron. First, we drive in the anchor with a thrust effect, and then install it by applying tension that will straighten the plate and compact the soil in order to stabilise the anchor. This type of anchor is particularly effective in soft ground and provides very good resistance to axial tension. It is indeed, a suitable for water bodies subject to strong currents or major fluctuations in water level.

Dead weight anchors

Dead weight anchoring is traditionally based on the use of concrete blocks or metal masses. This method is best suited to environments where it is not possible to perforate the ground with a liner, for example, or where there is a water table.

Pillar anchoring: a solution for frequent water level variations

Finally, pillar anchoring is a particularly suitable alternative for shallow areas and sites where water levels fluctuate frequently, such as in nearshore environments. This type of anchoring allows great adaptability to hydrological fluctuations while maintaining the stability of the floating system, particularly by reducing stresses on the mooring lines. This method keeps the lines at the same elevation as the island, so the lines are always taut.

We have deployed this type of solution on projects such as Changbin, located in an industrial bay in Taiwan, and also on ponds used for fish farming. In both these cases, the pillar anchor was perfectly suited to accompany the power plant as the water level varied all along the day. Thank to this anchoring technology, the floating solar plant can then rest on the ground when the tide came in.

Anchoring methods: analysis and reliable design

The importance of site analysis in anchoring design

The choice of anchoring methods and technologies depends on the site and its specific constraints. A thorough analysis of the site’s input data is essential for designing an optimal anchoring. Some of this data is essential for the correct sizing of the anchor:

- Bathymetry and topography allow the configuration of the water bed and variations in depth to be assessed.

- Water level fluctuations have a direct influence on the tension exerted on the mooring lines and must be taken into account when sizing them.

- Current analysis enables us to anticipate the dynamic forces that will be exerted on the floating system.

- Geotechnical studies, such as G2-AVP, are also necessary to determine the capacity of the soil to support different types of anchors, particularly screw or plate anchors.

- Finally, the dynamic pressure applied by winds and waves must be modelled to guarantee the stability and durability of the system.

At Ciel & Terre, we use this data as the design basis for each of our anchoring projects, drawing on our specific simulation tools and proven know-how.

Anchoring to the bank or bottom: choosing the right configuration

The first option : Anchoring to the bank

Bank anchoring involves fixing the mooring lines to the bank or close to the edge of the water body. This solution is generally preferred for deep lakes and reservoirs where the distances between the islands and the bank allow it and is accessible for the construction team. This solution is often quite cost competitive. Of course, the soil nature will determine the anchor techonology : either screws, plates, driven piles or chemical anchors.

The second method : Bottom anchoring

This technique involves placing anchor points directly on the bed of the body of water. Generally the method requires the use of floating barges to install the anchors on the lake bed. It can be applied to sites at significant depths where bank anchoring is not possible, particularly when the project includes several islands. Bottom anchoring can also absorb major fluctuations in water level. Various types of anchoring are possible, including the use of dead weight, screw anchors or plate anchors to ensure effective fixing.

Hybrid anchoring: combining bank and bottom anchoring to adapt to the topography of the site

In some cases, the type of site makes it appropriate to use a hybrid anchoring system, combining both bank and bottom anchoring. This type of configuration is often used when the floating solar power plant is positioned close to the banks on some of its sides, while remaining away from the banks on others. This approach makes it possible to optimise the mooring system’s design by adapting to the actual physical conditions of the water body.

At Ciel & Terre, we favour this solution when it minimises mooring line lengths, balances mechanical forces and reduces installation costs, while ensuring maximum system stability. Thanks to our expertise in different anchoring technologies (screw, plate or ballast anchors) and our design tools, we can dimension each component precisely according to the specific constraints of each fixing zone. Hybrid anchoring is therefore a flexible and proven solution for securing floating photovoltaic systems on complex sites.

Design tools for floating solar anchoring

The design of anchoring systems relies on modelling tools to anticipate environmental stresses and guarantee their structural integrity. At Ciel & Terre, we have developed our own tool, which we combine with specific analyses carried out on OrcaFlex to analyse the forces exerted on the mooring lines and optimise their layout. AutoCAD is then used to design detailed plans.

Our approach to sizing anchoring systems is based on a methodology certified by Bureau Veritas. This method incorporates technical assumptions and approaches that have been analysed by the Principia design office.

In addition, although the NR 493 standard from Bureau Veritas applies to the offshore sector, we have chosen to align ourselves with its requirements in terms of safety coefficients. This deliberately rigorous requirement reinforces the reliability of our designs, while adapting them specifically to the constraints of floating solar power.

Case Studies: Real Applications of Anchoring in Floating Solar

With several hundred projects installed around the world, we have accumulated solid experience in the field in implementing anchoring solutions for floating solar power. This diversity of environments enables us to meet a wide range of technical challenges, from great depths and wildly fluctuating water levels to sites that are difficult to access. Here are two examples of projects that illustrate our ability to adapt our solutions to the most complex conditions.

Maiwald project: optimised bank mooring

On the Maiwald project in Germany, we implemented a bank mooring with a ‘parabolic’ line. The project is located on a quarry lake that is still in operation, making part of the banks inaccessible. Our engineering teams therefore worked around the site environment and designed a parabolic line attached to the 2 opposite banks, allowing the power plant to be attached to this parabola.

This method optimised the anchoring of the floating solar power plant while reducing the complexity of the mooring system.

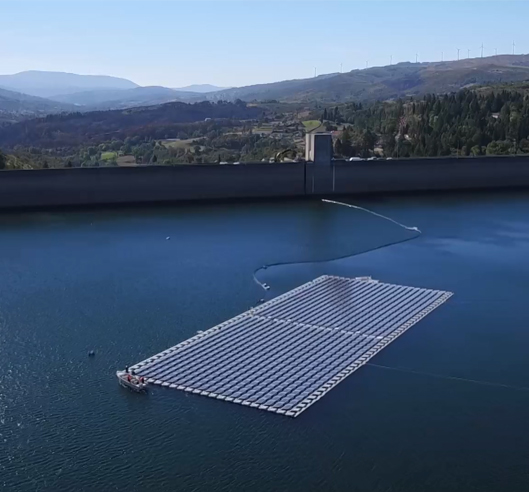

Alto Rabagão project: anchoring at the bottom and at depth

In the case of dams, specific challenges arise, particularly due to the great depth and variations in water level. Anchoring in these conditions must be designed to withstand currents, waves and the dam’s hydraulic activities.

This is the case for the Alto Rabagão project in Portugal. It required bottom anchoring, with anchor points placed at a depth of 50 metres. The design also took account of water level variations of up to 30 metres, demonstrating the adaptability of our anchoring solutions to extreme conditions.

Anchoring is a key factor in the success of floating photovoltaic projects. Careful selection of the technologies and methods used ensures the durability and performance of installations, even in complex environments. Thanks to advances in modelling, simulation tools integrated into our design process, and our recognised expertise, we can adapt the anchoring of floating solar power plants to a wide variety of sites, thereby contributing to the development of renewable energies. In addition, new design and installation methodologies maximise the efficiency of anchoring systems, ensuring their longevity and compliance with international standards.

By Chloé, marketing