The aim of our R&D lab is to test our floating solar products and solutions in all their dimensions and functions, so that we are sure that the solar plant will be efficient, safe, and profitable for at least 25 years. Thanks to this facility, we can accelerate the testing, and make sure the new products can be launched in full security. Testing floating solar solutions is one of the key success factor for a plant that is durable and reliable throughout its lifetime.

Floating solar performance cannot exist without checking reliability

The performance of our floating solar solutions is crucial to support the efficiency of the floating solar plants. As per the environment to which solar plants are being exposed, it must face many challenges. Over a period, different types of loads will be applied on the FPV projects: millions of movements because of the waves, currents, wind load and snow load come onto the FPV plant and its different elements: floats, anchoring system and PV module fixing system.

More information about these loads

and how we test them in the article:

Sobradinho FPV project, Brazil

1 MWp on a hydrodam

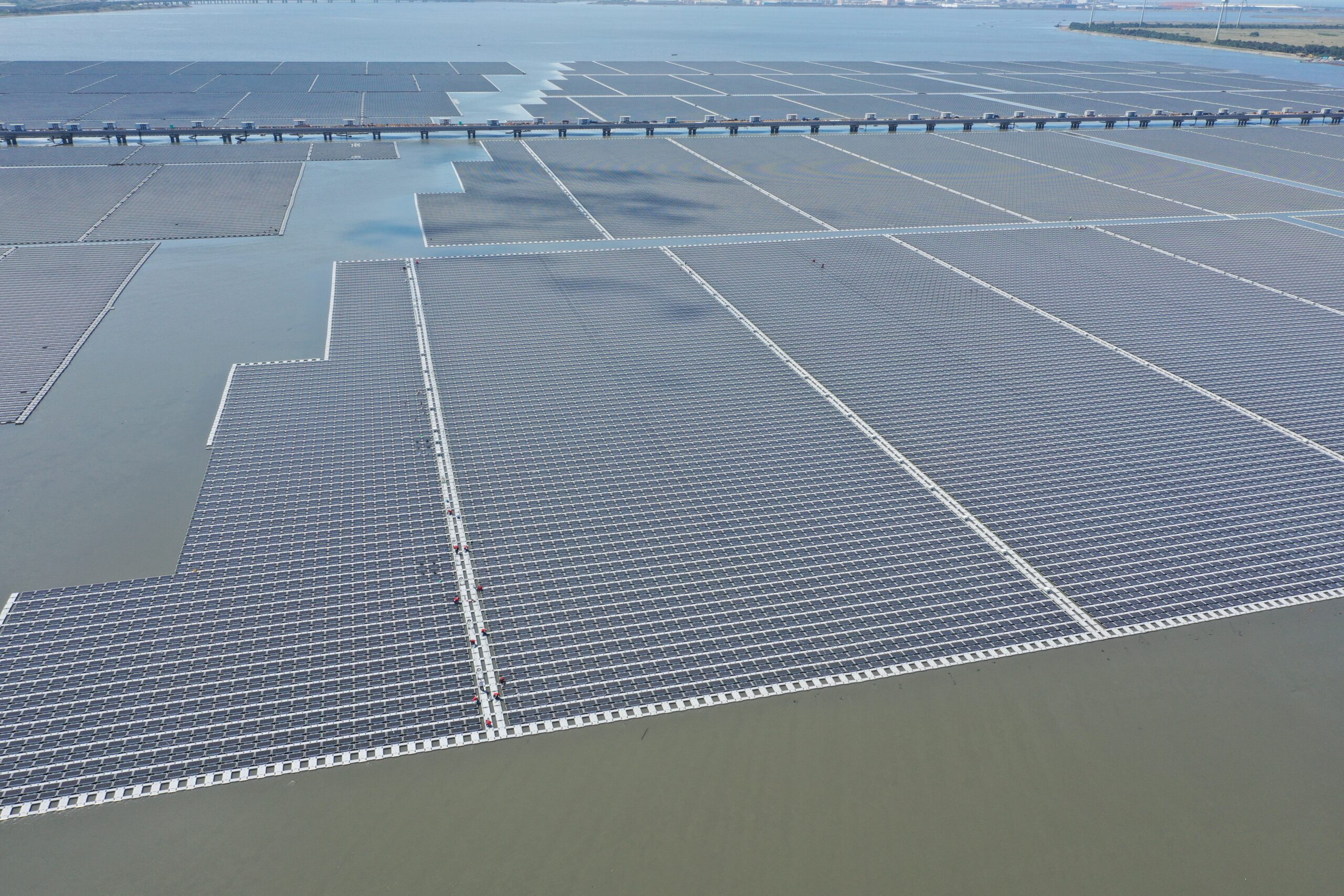

Changbin FPV project, Taiwan

88 MWp near shore

Kayamkulam FPV project, India

74 MWp on waterway

Testing solutions: a way to be more reactive and provide relevant technology in a fast-evolving market

At the same time, performing tests is a way to adapt to a fast-evolving market. Over the past years, the capacity of PV modules has kept on increasing for example, along with their size. In less than a dozen years, both PV panel size and capacity have almost doubled. We therefore redesigned our floating solar technology so that it could support the features of those new panels. This is the stage at which our R&D laboratory can bring a lot of changes: it will help to speed up the incubation stage into industrialization by testing the prototypes in all their aspects, help to optimize and develop a reliable product with the pace of the market, implying reactivity.

For example, our panel fixing system test bench has allowed us to quickly finalize a new PV fixation while ensuring the durability of our systems.

More generally, the reactivity permitted by our inhouse tests reduces the time to market by producing and testing our products in very close loops. The reason for this is that we can do very fast adaptations of our testing protocols and devices. We have for example already been able to launch a new PV fixation design in about six weeks from the date of receiving parts.

The need for quality insurance to exceed floating solar market standards

Being fast is valuable, but being fast, accurate and reliable is even better. As a pioneer of the floating solar market, our main objectives regarding our products are quality and performance. In testing our floating solar solutions, we have at heart to ensure that we exceed the market standards. To do so, we challenge the performance of our solutions by testing them in accelerated and extreme conditions.

Currently, the market standards are favorable to the democratization of floating solar, which is a positive perspective. To match our clients’ expectations relevantly, and to be in line with the approach, we must sustain the floating solar business, we feel we need to do more though. 30 years is the lifetime our stakeholders expect for their floating solar plants. This cannot be possible without checking the quality of our floating solar products and solutions. With testing, we can guarantee this lifetime even when our oldest projects reach 30% of this lifetime, and we apply our values of precision and integrity.

Quality is what makes FPV projects built with our floating solar platforms reliable and durable. Such characteristics undoubtedly lead to increasing bankability.

Find out more about our approach:

By Laura, Marketing

with the great collaboration of Jaison and Bharath, Tests & validation